Controlling dimensions as an innovative approach in modern-day engineering

Dimensional control with 3D scanning: how do so many businesses benefit from it?

In modern engineering, it’s easy to make a significant mistake. It can lead to schedule overloads, contract breaking, and even death. Controlling dimensions services help with preventing such catastrophes. Multiple businesses can vouch for that. Here’s why.

3D infrastructure maintenance

Dimensional 3D scanning is a technology used to capture the exact dimensions and shapes of physical objects. This process is essential in various industries, including manufacturing, construction, and quality control. It ensures that a bridge, for example, meets specified safety standards. Dimensional control can utilize different methods such as laser scanning, photogrammetry, or structured light, providing accurate 3D models. They are later used for analysis in terms of damage.

Infrastructure maintenance involves regular inspections. Professional dimensional control services speed up the process. Drones with specialized scanners are a revolutionary method that pinpoints all changes in particular structures as well as their positions. That ensures safety by extending the lifespan of assets and minimizing risks of failure or accidents.

Therefore, companies or local authorities can address even the smallest wear and tear issues. 3D scanning with drones provides an opportunity to implement repairs in time. As a result, a potentially devastating outcome can be prevented. Reduced costs in the long run are an additional benefit.

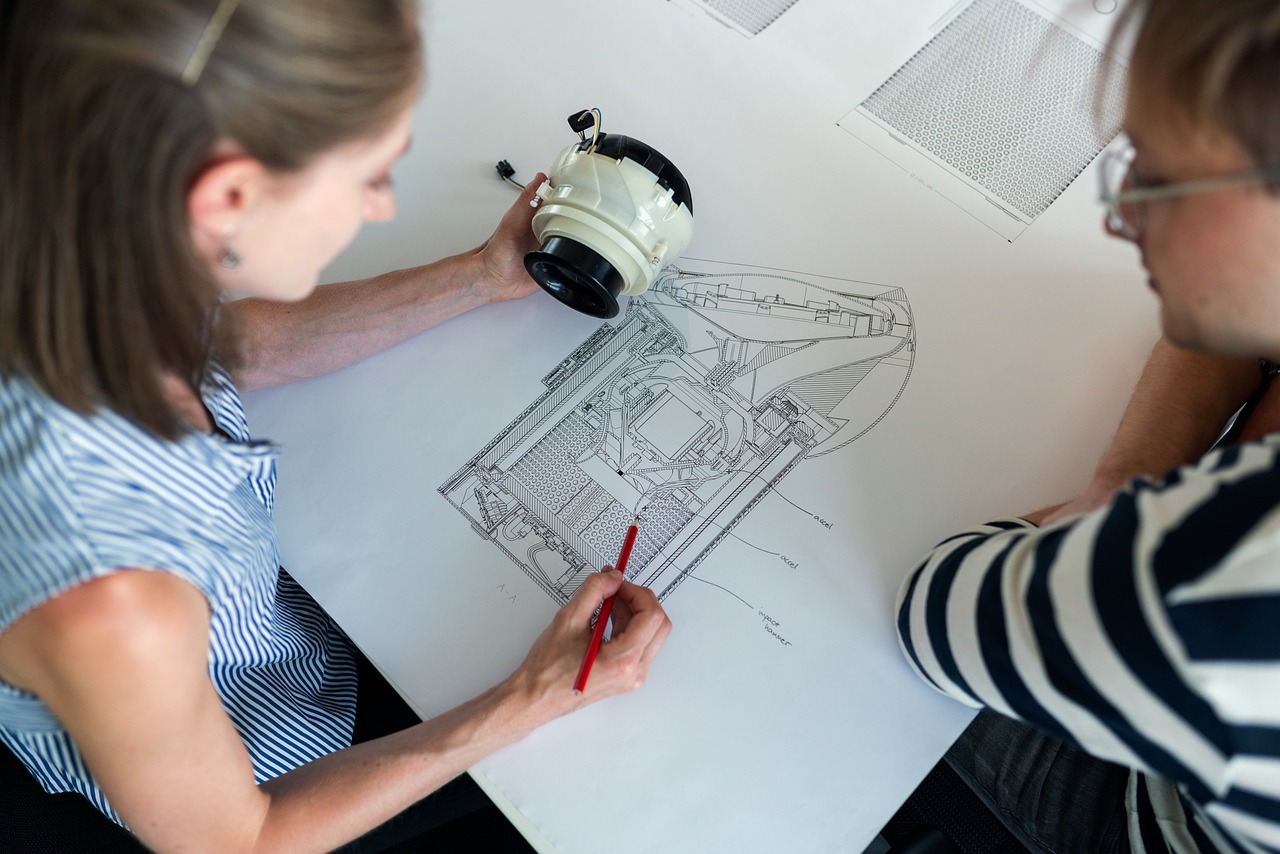

Dimensional control and reverse engineering

Precision is everything. Aerospace, automotive, or medical technology industries depend on it. They must make sure that particular components meet specific measurements and tolerances as set out in their design specifications. If not, consequences could lead to harsh financial losses.

Maintaining strict dimensional control is therefore crucial. Verifying dimensions at various stages of manufacturing ensures quality and compliance. Reverse engineering helps with that. It involves taking an existing product and deconstructing it to understand its design, functionality, and manufacturing processes. This technique is often used to replicate an item, improve upon it, or integrate it into a different system.

The usage of reverse engineering can involve physical disassembly as well as using technologies like 3D scanning to create digital models. Therefore, dimensional control in reverse engineering allows companies to refine designs, enhance quality, and streamline production processes with greater efficiency than ever before. The main focus is to save costs, ensure schedule compliance, and boost innovation.